Continuous High-Value Protein Production from Insect Cells

Could Replace Mammalian Cell Culture

Three-Way Partnership

InsectSelect

With demand for recombinant proteins reaching $13 billion a year and growing by 13% annually (according to Scrip, October, 1999), manufacturers are justifiably eager to use any expression system that works, including mammalian and insect cell culture. But mammalian cell culture is very pricey, while the major drawback of insect cell culture is that the cells must be lysed—equivalent to nuking your protein production "plant"—to reach the high-value recombinant product. A new, continuous gene expression system available for license from Research Corporation Technologies (RCT; Tucson, AZ) could change that.

Applicable to a wide range of insect culture systems, the InsectSelect expression system uses cultured insect cells to produce almost any peptide or protein, including cytokines and growth factors, peptide hormones, and anti-infective protein drugs. Because it's scalable, InsectSelect may be used in the earliest discovery stages through production, presumably even for kilogram quantities of therapeutic proteins.

Could Replace Mammalian Cell Culture (Back to Top)

Researchers currently use bacteria, yeast, insect and mammalian cells to produce recombinant proteins. This process requires an expression vector—often a virus—to carry a gene coding for a specific protein into the host cell. After production in culture, the protein is extracted and purified for use mainly in therapeutics, vaccines, and diagnostics.

Insect expression systems are popular because they can make and secrete complex, high-value proteins that once could only be produced in mammalian systems at much higher costs. Traditional insect expression systems use baculovirus vectors to insert foreign genes into insect cells. Unfortunately the baculovirus (a pathogen of caterpillars) causes the host cell membrane to rupture, lose cytoplasm, and release new viral particles. Protein production in such systems yield a complex cell-lysate and crude mixture of proteins. If that were not bad enough, released target proteins are subject to proteases that also spill out of the cell during lysis.

InsectSelect is non-lytic, so cells remain intact as they churn out high-value proteins. That opens possibilities for continuous expression, analysis, and purification of recombinant proteins without disturbing the expression system. Using a stable, plasmid-based vector instead of baculovirus vectors, InsectSelect simplifies protein expression by eliminating the need to generate and amplify viral stocks and reinfect host cells. Yields are quite good, ranging from 2 to 15 mg/liter.

Three-Way Partnership (Back to Top)

The technology behind InsectSelect was developed at the University of British Columbia, but commercialization was achieved through a strategic partnership among RCT, the university, and Invitrogen Corp. (Carlsbad, CA), which manufactures and sells InsectSelect.

RCT is the "point man" in the commercialization of InsectSelect. The university developers charged RTC with finding a licensee; RTC turned to Invitrogen, which now manufactures and sells InsectSelect as well as other expression vectors and reagents. Invitrogen had previously licensed a yeast expression system, based on Pichia pastoris, from Philips Petroleum, so they were a logical choice for manufacturing InsectSelect. The Pichia expression system, also owned by RCT, has about 70 licensees worldwide.

"We had experience with Invitrogen through the Pichia deal," says Ben Cohen, who heads RCT's licensing efforts for gene expression products, "so we felt comfortable with their ability to commercialize InsectSelect. The way it stands, everybody involved is doing what they do best."

RCT does not simply shop technologies to the first taker, according to Cohen. "We take ownership of the technologies we acquire and seek the best value for ourselves as well as the developer. It's not a question of simply getting anyone to take a license. What we do requires extensive management and monitoring."

InsectSelect (Back to Top)

All components of InsectSelect are tested to ensure reproducible results and high quality:

- Plasmid vectors are qualified by restriction enzyme digestion.

- Sequencing primers are qualified by automated DNA sequencing.

- Zeocin (a resistance gene) is functionally qualified by kill-curve experiment.

- Frozen insect cell stocks are qualified by measuring viability following recovery.

- Unsect cell culture medium is qualified by showing that it maintains insect cells in culture with doubling times between 18 and 24 hours and >98% viability.

- InsectinPlus transfection reagent is qualified by transfection of insect cells.

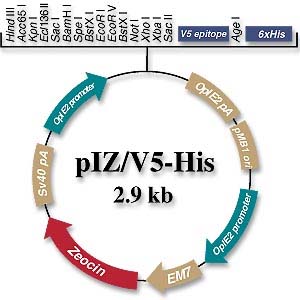

The InsectSelect expression vector pIZT/V5-His is a small vector with several features that facilitate high-level expression, analysis, and detection of recombinant proteins in insect cells:

- OpMNPV IE2 promoter for high-level expression of genes cloned into the large multiple-cloning site

- Zeocin resistance gene for rapid selection of stably transfected cell lines

- C-terminal V5 epitope for detection with an Anti-V5 antibodies

- C-terminal polyhistidine (6xHis) sequence for rapid purification with Invitrogen's ProBond resin

- Forward and reverse sequencing primers for verification of inframe cloning with the fusion tag

InvitroGen also sells reagents and kits to make InsectSelect work better for specific applications. These include serum-free media, accessory primers, vector kits, and "glow" kits for rapid identification of transfections.

For more information: Bennett N. Cohen, Director of Commercialization, RCT, 101 North Wilmot Rd., Suite 600, Tucson, AZ 85711-3365. Tel: 520-748-4443. Fax: 520-748-0025.

Mark Walker, National Sales Manager, Invitrogen, 1600 Faraday Ave, Carlsbad CA 92008. Tel: 760-603-7200, ext. 281. Fax: 760-603-7201.

By Angelo DePalma